Table of Contents

1. Types of Tuck Boxes and Their Application

3. Creating Print-Ready Artwork: A Guide to Success

Introduction

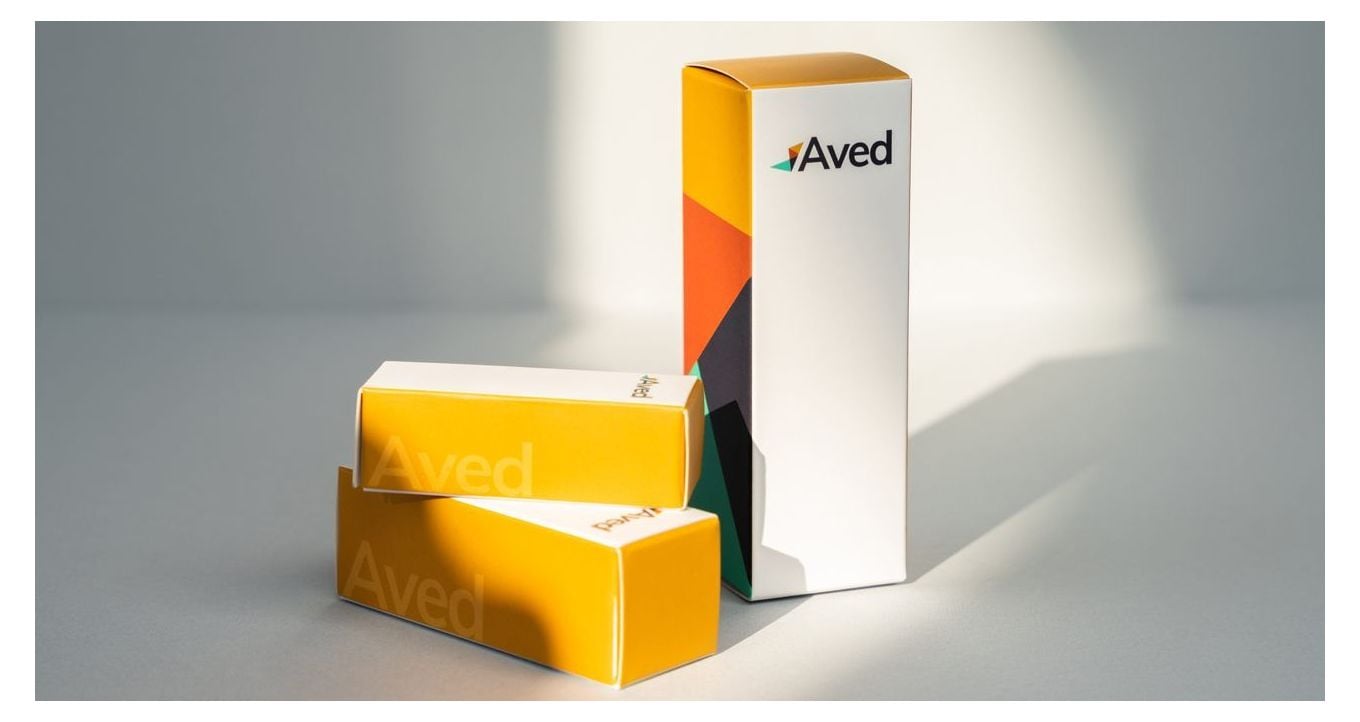

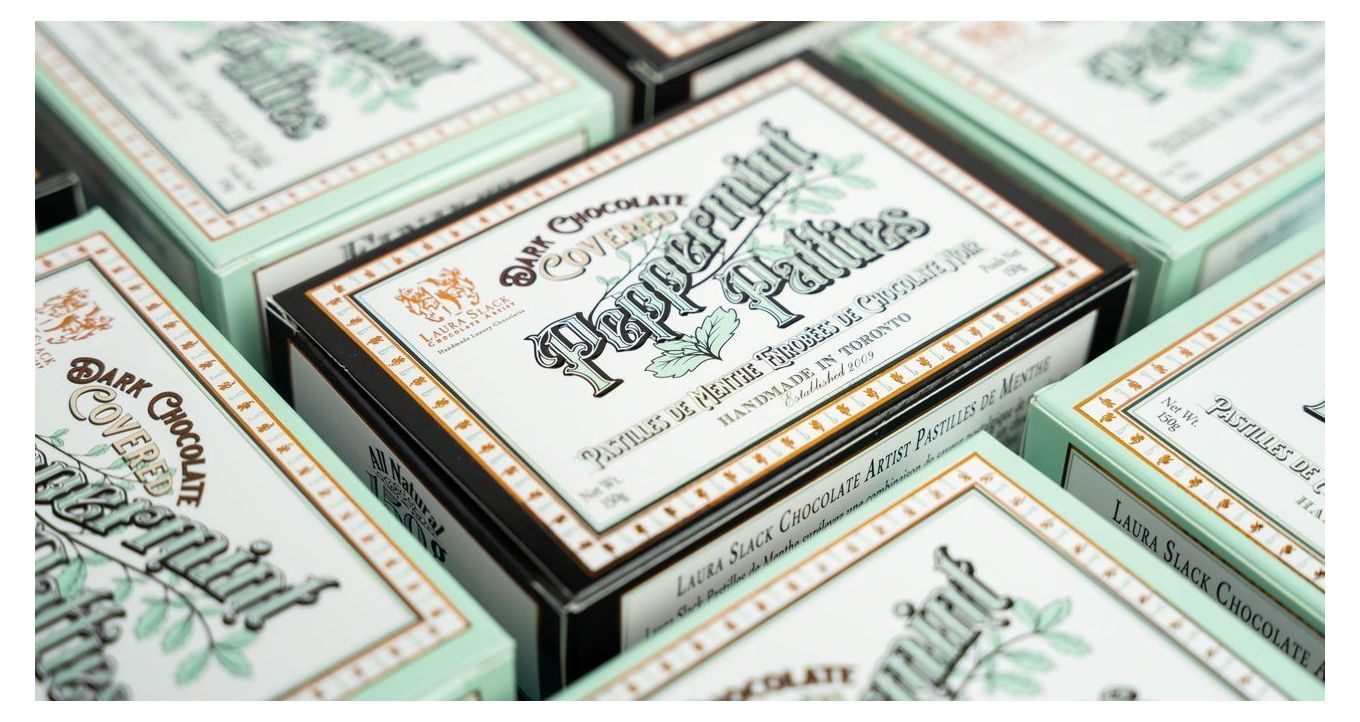

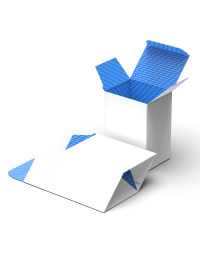

Are you a business owner on the hunt for the perfect packaging solution that suits your company's unique needs? Let us introduce you to custom tuck boxes, a practical solution for business owners who want an easily customizable, versatile, and structurally durable packaging solution. Let's start by diving into what precisely tuck-end boxes are. Essentially, a tuck end box is paperboard packaging with flaps on either end that tuck into the box to secure the contents. These boxes are trendy due to their versatility and ease of assembly. Whether packaging cosmetics, pharmaceutical items, food items, or electronics, custom-printed tuck boxes provide a reliable and appealing solution.

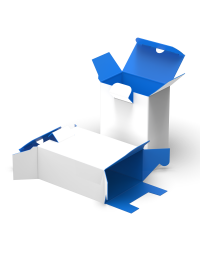

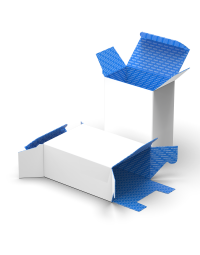

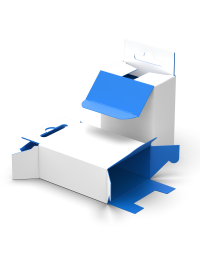

To fully appreciate the functionality of custom tuck boxes, it's essential to understand their key components. Tuck end boxes consist of the following features: a lid, The top flap that opens to access the contents inside the box, and a base, the main body of the box that holds the product. Tuck end boxes also include flaps, which are side pieces that tuck into the box, securing the lid and base together. All these elements work together to create a sturdy and reliable packaging option that's easy to assemble and use. At Newprint, we offer custom-printed tuck boxes tailored to your product's requirements. Ready to elevate your packaging game? Let's explore how these custom tuck boxes can do just that!

1. Types of Tuck Boxes and Their Application

Custom tuck boxes offer a world of possibilities for your products. From reverse tuck-end boxes to straight tuck-end boxes with unique features, explore the range of custom tuck end boxes below to find the ideal packaging solution tailored to your needs.

a. Tuck-End Boxes:

-

Reverse Tuck-End Box: Custom reverse tuck boxes, or RTEs, are perfect for storing small to medium jars, tubes, bottles, and blister packs. These tuck end boxes have closing flaps on opposite sides and are easy to assemble by hand or machine. They can be customized with Uncoated, Coated, or Kraft paper and enhanced with finishes like lamination, UV coating, and embossing. And most importantly, we offer eco-friendly options as well, ensuring sustainable packaging without compromising on quality or aesthetics.

-

Reverse Tuck-End Box with Tongue Lock: The reverse tuck end box with top and bottom tongue lock is a versatile and secure packaging option. This box features flaps that tuck opposite directions on the top and bottom, with tongue locks that provide extra security, and these boxes are shipped pre-glued and flattened for your convenience. With high-quality printing, these custom tuck-top boxes enhance your product's presentation and protection!

-

Straight Tuck-End Boxes: A straight tuck end box is famous for its clean, seamless look. The top and bottom flaps tuck into the same side, providing easy assembly and a polished appearance. Ideal for lightweight products like small electronics, these custom tuck boxes can be fully customized with your branding.

-

Straight Tuck-End Box with Sombrero Hole on Header: These custom tuck boxes feature a sombrero hole on the header, allowing them to hang conveniently for retail display. Ideal for lightweight to medium-weight products, these custom-printed tuck boxes ensure your items are showcased attractively while remaining secure.

b. Lock-Bottom Boxes:

-

Auto Bottom Box with Tuck Top: The Auto Bottom Box with a Tuck Top is a versatile and sturdy packaging solution. The design consists of an automatic bottom closure. However, these custom tuck boxes can also be glued at the bottom, making them more secure for medium to heavy-weight products like food, electronics, and cosmetics.

-

1-2-3 Lock Bottom Box with Tuck Top: The 1-2-3 lock bottom box with a tuck top offers security and durability, making it ideal for heavier items like cosmetic creams. These custom-printed tuck boxes are easy to assemble in three steps and are versatile for various products. Custom tuck-top boxes can be tailored with different paper options and finishes, ensuring your packaging is functional and visually appealing.

c. Roll End Tuck Boxes:

- Roll-End Tuck Top Boxes: The roll-end tuck top boxes are easy to assemble, don’t require any glueing, and feature a tray-like base with an attached lid. For retail display, these custom tuck-top boxes are perfect for items like clothing, accessories, baked goods, and electronics. Custom-printed tuck boxes can be tailored with various paper options and finishes to match your brand's needs.

-

Die Cut Printing: Our capabilities allow you to create unique shapes and designs, adding a dynamic element to your custom tuck boxes.

-

Embossing: Embossing adds a touch of elegance by raising specific areas, giving your custom-printed tuck boxes a tactile, 3D effect, perfect for highlighting logos or unique designs.

-

Foil Stamping: Elevate your tuck end boxes with foil stamping, which uses metallic foil to create eye-catching accents, adding a luxurious feel.

-

Spot Colours: Ensure precise colour matching across all your custom tuck end boxes and custom reverse tuck boxes with spot colours and Pantone inks, maintaining brand consistency.

-

Diverse Lamination Options: You can enhance the durability and finish of your packaging with lamination options like matte, gloss, and soft-touch, each providing a distinct look and feel while offering extra protection.

-

Dieline: Start by using our website to generate custom dielines tailored to your custom tuck-top boxes. A precise dieline is essential for accurate cutting and folding.

-

Bleed: Always include a bleed of 0.125 inches on all sides. This extra space ensures that your design extends to the edge of the box without any white borders.

-

Colour Mode: When designing, make sure to use the CMYK colour mode for the best printing results. If necessary, incorporate spot colours to maintain brand accuracy. These colour modes are industry standards for printing and will make your custom-printed tuck boxes stand out.

-

High-Resolution Images: Ensure all images are high resolution (at least 300 DPI). This prevents pixelation or blurriness in your final design, ensuring your custom tuck-top boxes look sharp and professional.

- Fonts: Embed all fonts in your design file. This avoids font substitution issues and keeps your text exactly how intended.

-

Custom-printed tuck boxes are versatile, practical and durable packaging options for varying products.

-

At Newprint, we can print and manufacture various tuck end boxes!

-

Reverse Tuck-End Box: Suitable for small to medium jars, tubes, bottles, and blister packs.

-

Reverse Tuck-End Box with Tongue Lock: Provides extra security making it ideal for enhanced product protection.

-

Straight Tuck-End Box: Clean, seamless look, suitable for lightweight products.

-

Straight Tuck-End Box with Sombrero Hole: Ideal for retail display with added hanging convenience.

-

Auto Bottom Box with Tuck Top: Versatile, sturdy, suitable for medium to heavy-weight products.

-

1-2-3 Lock Bottom Box with Tuck Top: Easy to assemble, ideal for heavier items like cosmetic creams.

-

Roll-End Tuck Top Boxes: Tray-like base with lid, perfect for retail display of items like clothing and baked goods.

-

-

Environmental sustainability is our top priority. This is why we can customize your packaging order to include eco-conscious materials like FSC-certified paper made from recycled paper.

-

We offer a great range of services like die-cut printing, embossing, foil stamping, spot colours, and lamination to customize your order.

-

If your artwork file for your packaging project has the following: A dieline, 0.125-inch bleed, CMYK colour mode, embedded fonts, or high-resolution images. You’re ready to print!

2. Customization Options

Why settle for ordinary when you can go green with our recycled fiber options? Our custom tuck boxes are crafted using premium recycled paperboard, reducing environmental impact without compromising quality. At Newprint, we proudly offer FSC-certified paper; this paper comes from responsibly managed forests, promoting biodiversity and supporting communities. Make a statement with eco-conscious materials like recycled fiber and FSC-certified paper. And when it comes to aesthetics, we have some fantastic embellishment options to make your custom tuck-top boxes stand out.

3. Creating Print-Ready Artwork: A Guide to Success

Now that you're all caught up on what custom-printed tuck boxes are. Let's move on to setting up print-ready files! Ensuring your custom tuck boxes are perfect is crucial for a flawless final product. Here's what you need to know.

4. Key Takeaways:

Conclusion

Steve Jobs famously said:

“Packaging can be theatre, it can create a story.”

Custom printed packaging goes beyond merely protecting a product; it serves as an essential tool in storytelling and branding. In the words of Steve Jobs, effective packaging can transform a simple product into an engaging experience. Ready to turn your packaging into an experience? Email us at [email protected] or follow these tips to create gorgeous, print-ready artwork for your custom-printed tuck boxes. And remember, Newprint is here to assist you every step of the way!